PP/PE Recycling and Water-ring Granulating Machine Line

- group name

- Plastic Pelletizing&Granulating System

- Min Order

- 1 set

- brand name

- FOSITA

- model

- FST

- Nearest port for product export

- SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, Westem Union, Cash

- update time

- Mon, 26 Aug 2019 10:01:57 GMT

Paramtents

Type Granulating Production Line

Voltage 380V

Power 37-132kw

Dimension(L*W*H) 10000*1200*1500MM

Weight 5-10T

Certificaiton CE ISO

Warranty 1 year

After-sales Service Engineer available for service overseas

Screw material 38CrMoAlA

Supply Ability 10 Set/Sets per Month

Pelletizing Method Water-ring Cutting

Factory Place 2 hours from Shanghai

Packging & Delivery

-

Min Order1 set

Briefing

The extruding die face cutting granulating line is for plastics such as LDPE,HDPE,PP,recycling granulating(pelletizing).

Detailed

Products Description

★ This plastic recycling and water-ring granulating system is suitable for many waste film recycling and making pellets,such as PP, HDPE, LDPE film and clean woven bag material, etc,.

★ This film can be cut and compressed in agglomerator and then feed into extruder.According to our design,we make sure this machine has a long working life and ecnomical efficiency in using.

★ You can choose use single stage or double stage plastic film granulating machine according to how clean your material.

Plastic Films

Woven Bags

Plastic Bags

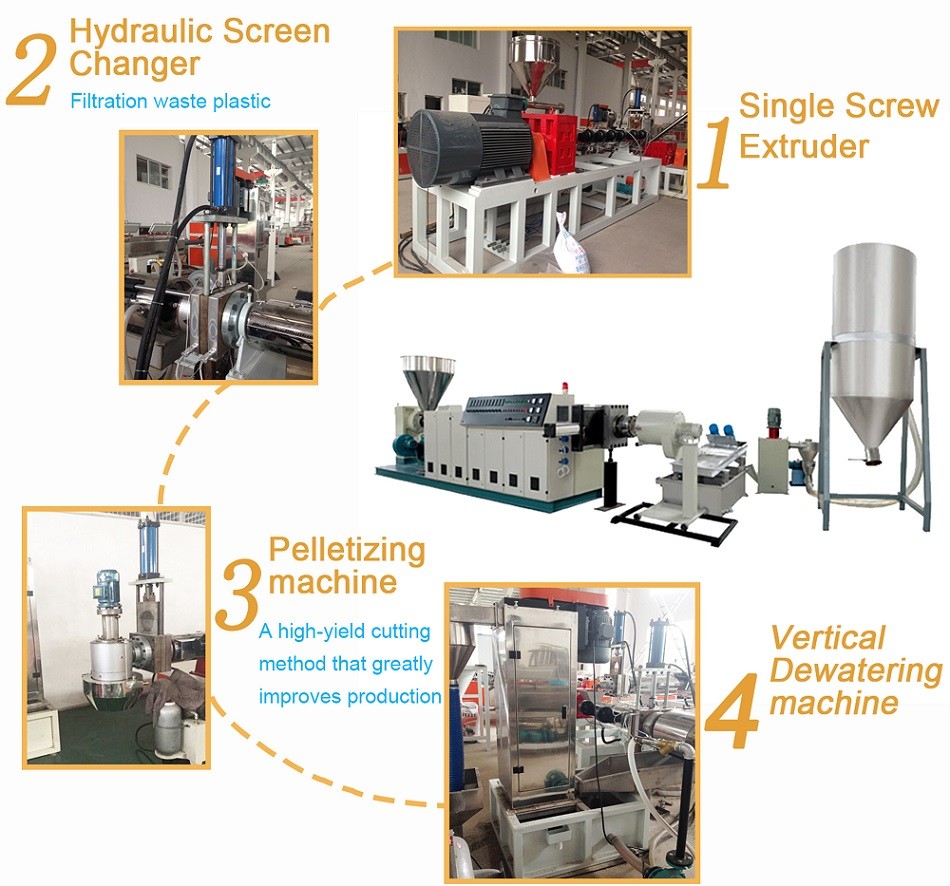

Working Procedure

Technical Parameters

|

Pipe Line Model

|

Extruder Model

|

Output(kg/h)

|

Line length(m0

|

|

FST-150

|

SJ100

|

80-150

|

12

|

|

FST-300

|

SJ120

|

200-300

|

18

|

|

FST-500

|

TSK95

|

400-500

|

22

|

Working Video

Final Products