Plastic Agglomerator machine for film washing and recycling

- group name

- Plastic Pelletizing&Granulating System

- Min Order

- 1 set

- brand name

- FOSITA

- model

- FST-GSL

- Nearest port for product export

- SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, Westem Union, Cash

- update time

- Mon, 24 Jun 2019 10:15:04 GMT

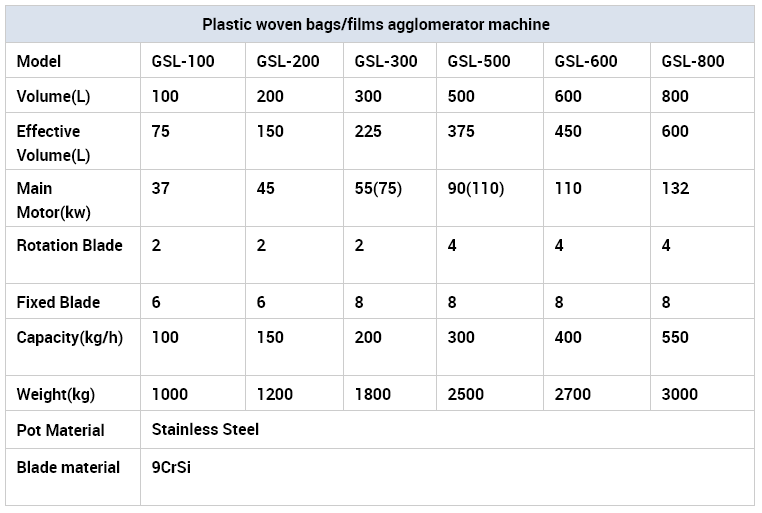

Paramtents

Place of Origin Jiangsu, China (Mainland)

Power 37-132 KW

Dimension 1700 X750 X1500

Weight 1000kg

Certification CE

Warranty 1 Year

Color Customer Demand

Application Plastic Compounding

Packging & Delivery

-

Min Order1 set

Briefing

The machine is mainly suitable for processing complete film,plastic bags and fibber into small granules,

Detailed

Production Description

Product Application

Waste Plastic Film, Woven Bags Agglomerator /Compactor Machine is mainly suitable for processing complete film,plastic bags and fibber into small granules,the final granules can be used for send into extruder to pelletizing again.

Waste Plastic Film, Woven Bags Agglomerator /Compactor Machine is mainly suitable for processing complete film,plastic bags and fibber into small granules,the final granules can be used for send into extruder to pelletizing again.

Working Video

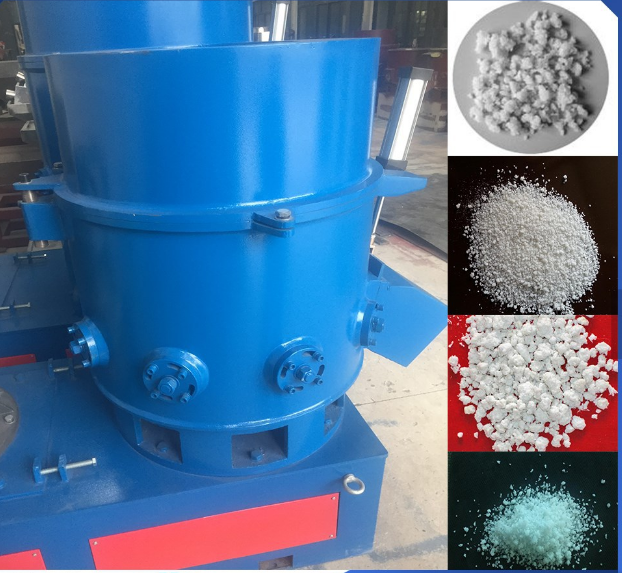

Products Show

Features of Plastic Film Compactor Agglomerator:

This Plastic Film Compactor Agglomerator is mainly suitable for processing complete film,plastic bags and fibber into small granules,the final granules can be used for send into extruder to pelletizing again.

1.strong design of double bearing for holding the main shaft

2. High performance blades

3.Water flushing automatically

4.Motor power:37KW-132KW

5.Capacity:100-800kg/h

This Plastic Film Compactor Agglomerator is mainly suitable for processing complete film,plastic bags and fibber into small granules,the final granules can be used for send into extruder to pelletizing again.

1.strong design of double bearing for holding the main shaft

2. High performance blades

3.Water flushing automatically

4.Motor power:37KW-132KW

5.Capacity:100-800kg/h

Product Details

Applicable material of Plastic Film Compactor Agglomerator:

Soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fibers and other thermoplastics,etc.

When the waste plastic is supplied into the chamber, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization.

Soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fibers and other thermoplastics,etc.

When the waste plastic is supplied into the chamber, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization.

Contact us