Plastic Pelletizing Machine with Compactor Design Granulating System Manufacturer Fosita Company

- group name

- Plastic Pelletizing&Granulating System

- Min Order

- 1 set

- brand name

- FOSITA

- model

- FST-100/300/500

- Nearest port for product export

- SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, Westem Union, Cash

- update time

- Mon, 20 Jul 2020 09:53:35 GMT

Paramtents

Power 90kw

Output 200-1000kg/h

Dimension(L*W*H) 10000*1200*1500MM

Certification CE ISO9001

Raw material recycled PP/PE LDPE films and raffias

After-sales Service Engineer Overseas Service

Application Granules Production

Final product shape Pellets/Granules

Pelletizing Type Water ring die-face hot pelletizing

Factory location 2 hours from shanghai

Packging & Delivery

-

Min Order1 set

Briefing

This line is of new design, reasonable configuration, steady operation, low noise, low consumption and high output.

Detailed

Product Description

This plastic pelletizing machine can used for granulating many kind of raw material such as plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions are in the form of pellets/granules, which can directly put into the production line for blowing moulding machine, plastics injection machine, etc.

Working Process

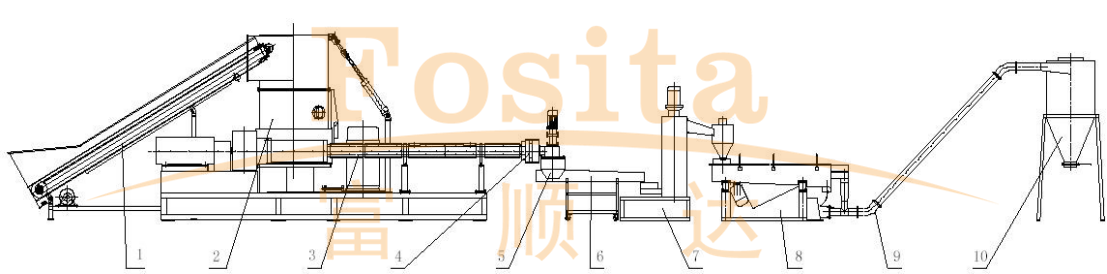

|

No.

|

Machine Name&Type

|

Quantity

|

Remark

|

|

1

|

Belt Conveyor

|

1 Set

|

Film Feeding

|

2 | Compactor | 1 Set | Film Compactor |

3 | Single Screw Extruder | 1 Set | Venting System |

4 | Hydralic Screen Changer | 1 Set | Non-stop changing the net |

|

5

|

Water-ring Cutter

|

1 Set

|

Horizontal or Vertical

|

|

6

|

Spin-Dryer

|

1 Set

|

Vertical Type

|

Process flow of plastic granulating machine :

Convey feeder→Compactor→Extruding machine→ High speed screen exchanger→ water-ring pelletizing machine (or strand cutting)→Spin Dryer → Storage silo

Technical Parameter

|

Pipe Line Model

|

Extruder Model

|

Output(kg/h)

|

Line Length(m)

|

|

FST-150

|

SJ100

|

200

|

10

|

|

FST-300

|

SJ120

|

550

|

15

|

|

FST-500

|

SJ150

|

1000

|

20

|

Suggestions for you

We suggest you choose suitable machines according to your capacity, material and other requirements.

After machine tested and been delivered to your factory. We can also provide training service for your workers with experienced engineers.

So if you're looking for plastic granule making pelletizing machine, please contact us without any hesitation.

We'll provide better quality machine and better service for you.